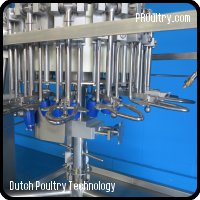

Final Inspection Machine Alerta

A product of Dutch Poultry Technology

Price and Availability

Price and Availability

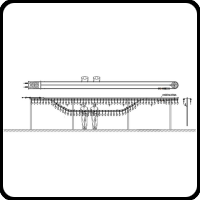

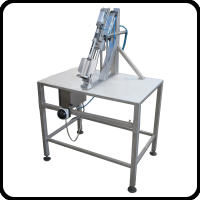

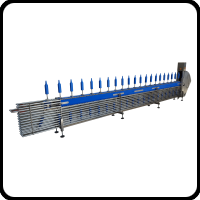

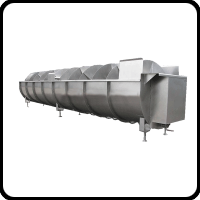

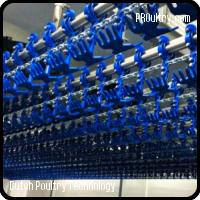

The final inspection machine is designed to clean the abdominal cavity of each carcass. Any remaining parts, such as lungs and other small residual tissues, are removed by a vacuum-powered suction head. The rotating machine holds up to 20 units. As each bird is conveyed through the machine, its suction units enter the birds’ cavity. Once the bottom is reached, the vacuum system activates and removes the birds’ lungs and other loose materials. After this task has been completed, vacuum is turned off and the units leave the carcass.

- Driven by an overhead conveyor

- Quick removal of remaining impurities in the carcass by vacuum

- Machine is easy to maintain

- Reduced noise level due to special air valve

- Quick and easy cleaning

- Improving shelf life: machine to be placed after the inside outside washer

- Made of stainless steel and other non corrosive materials

- Supplied with receiving bin with central drain

- High quality design

Product Videos 1 video

Related categories Final Inspection Machine 1 Category

3-.Evisceration and chillingRelated Products 1 Product

Other products of Dutch Poultry Technology 1 producto

Product Website

http://www.dutch-poultry-tech.com/shop/evisceration/final-inspection-machine/Dutch Poultry Technology

DUTCH POULTRY TECHNOLOGY B.V. is a Dutch manufacturing and engineering company specialized in the design, manufacturing and installation of cost-effective, reliable, easy to install and operate poultry processing solutions for processing 500 – 6000 birds per hour.

Our semi- and full automatic processing solutions are based on proven technology and 30+ years of automatic processing experience. Lean engineering and manufacturing greatly reduce production, installation and operation costs.

See company

Our semi- and full automatic processing solutions are based on proven technology and 30+ years of automatic processing experience. Lean engineering and manufacturing greatly reduce production, installation and operation costs.

See company

Price and product availability