Vent Cutter Alerta

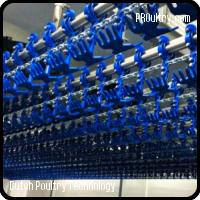

A product of Dutch Poultry Technology

Price and Availability

Price and Availability

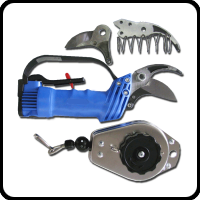

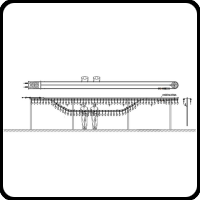

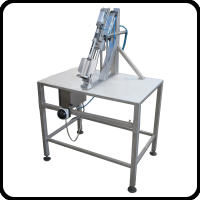

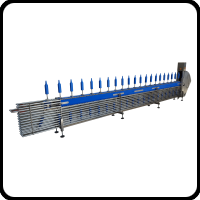

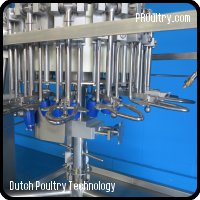

The Vent Cutter is the first machine in the automatic evisceration line. It has a cylindrical, rotating knife which is used to make a circular cut around the vent of the bird. When the knife withdraws, it pulls out the vent without damaging or cutting the intestines. In addition the Bursa of Fabricius, an organ in the cloaca area, is removed. Depending on the number of working units a capacity of up to 3000 (7 units) or 6000 (14 units) birds per hour can be achieved. The Automatic Vent Cutter ensures an efficient, precise and clean cut without any damage or subsequent risks at contamination. While the number of processing units may vary, it is also possible to operate with various knife sizes. Naturally, a larger bird requires a knife with a larger diameter and vice versa. After each production cycle, the units are cleaned to reduce the risk at cross contamination.

- driven by an overhead conveyor

- integral part of an automatic evisceration line

- Specially developed to separate the vent, including Bursa of Fabricius, from the broiler without causing any damage

- Optimum stretching of the broiler and separation of the Bursa

- Completely mechanic process: vacuum is recommended for hygienic purposes

- Safety sensor which automatically halts the evisceration line upon detecting a machine jam of breakdown, preventing further damage to the line

- No damage to intestines and back

- Automatic cleaning of vent cutting units

- Made of stainless steel and other non-corrosive materials

- Supplied with receiving bin and central drain

- Height adjustment device

Product Videos 1 video

Related categories Vent Cutter 1 Category

3-.Evisceration and chillingRelated Products 1 Product

Other products of Dutch Poultry Technology 1 producto

Product Website

http://www.dutch-poultry-tech.com/shop/evisceration/vent-cutter/Dutch Poultry Technology

DUTCH POULTRY TECHNOLOGY B.V. is a Dutch manufacturing and engineering company specialized in the design, manufacturing and installation of cost-effective, reliable, easy to install and operate poultry processing solutions for processing 500 – 6000 birds per hour.

Our semi- and full automatic processing solutions are based on proven technology and 30+ years of automatic processing experience. Lean engineering and manufacturing greatly reduce production, installation and operation costs.

See company

Our semi- and full automatic processing solutions are based on proven technology and 30+ years of automatic processing experience. Lean engineering and manufacturing greatly reduce production, installation and operation costs.

See company

Price and product availability