Dutch Poultry Technology

Hillegom, The Netherlands,

25+

(HOLANDA)

1 Products

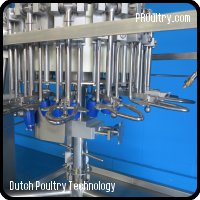

Automatic Evisceration

Automatic evisceration is the pinnacle of modern poultry processing. Manual processing requires a large number of staff. However, automated eviscerating line greatly reduces needed labour. Therefore the technology allows for expanded production capacities of 4 ...

View productVent Cutting Pistol

- Vacuum-powered vent cutting pistol which cuts the vent hole of the bird.

- Precise and efficient vent removal.

- A cost-effective tool to semi-automate the evisceration process and reduce line personnel.cost-effective tool to semi-automate the evisceration

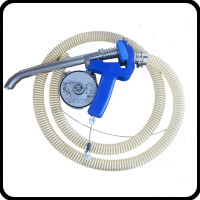

Lung Removal Gun

- The Lung Gun is designed to effectively remove lungs and other small residual tissues by means of vacuum.

- It is used at a working station of an evisceration trough, alongside other tools to semi-automate the evisceration process

- Suitable for broilers;

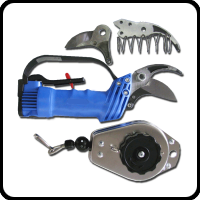

Hock/Neck Scissor

- device can be used to cut hocks, feet or necks (depending on utilized knife)

- capacity of up to 1000 birds per hour

- operated with compressed air (scope of supply doesn’t include a compressor)

- including air hose

- Optional weight balancer to reduce ope

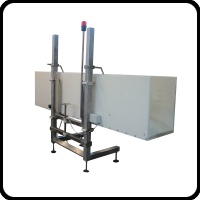

Vacuum Offal System

- The Vacuum Transport system for handling and transporting inedible offal waste like blood and lungs

- The system can be connected to a bleeding trough, automatic final inspection machine or semi-automatic vent cutting or lung pistols

- The setup consists of

Offal/Water Separator

6-.Cooling, Sorting, Packaging and end of line

- Offal Water Separator – Designed for separating feathers or offal from excess water

- Perforated drum sieve which acts as a centrifuge

- Made of stainless steel and other non-corrosive materials

- High quality design

- Height adjustable

- Optional: spray no

Dry Offal System

Compressed Air Offal Transport is a method of dry offal transport using blow pots to blow offal waste to designated harvesting areas. An advantage of dry transport systems is that they do not use any water.

- A cost-effective solution solution for handling p

Bird Counter

1-.Arrival and Live Bird Handling

The automatic bird counter can be installed at various places in a poultry processing plants for management information and controlling purposes. Generally the counter is placed before or near the bleed line to count live birds. An optical sensor detects each ...

View productWeighing Line

- With this weighing line you can meet the demands of your customers by giving them the accuracy they require, in the weight class they want, at minimum costs and minimum give-away.

- It is also possible to read out the weight of each flock processed (gause c

Wing Portioner

5-.Cut-up, Deboning, Skinning, Portioning and Slicing

http://www.dutch-poultry-tech.com/shop/cut-up-deboning/wing-portioner/

- Wing Portioner machine which cuts wings in two or three parts (drumettes, flaps, tips);

- a rotating wheel guides the wings over fixed knives;

- economical set-up which takes very littl

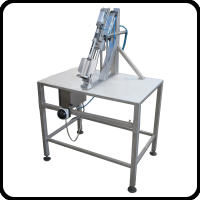

Single Thigh Deboner

5-.Cut-up, Deboning, Skinning, Portioning and Slicing

- Semi-automatic thigh deboner for deboning up to 300 thighs per hour (depending on operator skill and product characteristics);

- Based on the industry tested and proven “diaphragm” principle: thigh is placed on a diaphragm (rubber disc with a hole in it) wh

Manual Cut-up Saw

5-.Cut-up, Deboning, Skinning, Portioning and Slicing

It is economically feasible to choose automatic cut-up starting from 2000 birds per hour and upwards. At lower capacities however, there are cost-effective tools available to enable clean, efficient cuts without making large investments into automatic systems. ...

View productDrum / Thigh Deboner

5-.Cut-up, Deboning, Skinning, Portioning and Slicing

The Thigh Deboner is specially designed to debone dark meat, meaning thighs and drums, in a cost-effective and efficient manner. The machine is based on the industry-tested “diaphragm” principle. The main parts of the deboning units are a rubber disc with a ho ...

View productCone Debone Line

5-.Cut-up, Deboning, Skinning, Portioning and Slicing

The Cone Debone Line enables an efficient portioning and deboning of whole birds or pieces (such as breasts).

- Ergonomic, reliable design to debone or portion birds;

- Product is fixed on food-industry approved nylon cones;

- As the line runs, the product

Automatic Cut-up Line

5-.Cut-up, Deboning, Skinning, Portioning and Slicing

Choose one of two efficient Cut-up Line setups for portioning up to 2000 birds per hour.

- Wing Cutter, Horizontal Halving (optional Pre-cutter), Saddle Splitter, Thigh/Drum Separator

- Wing Cutter, Breast Cap Cutter, Leg Processor, Thigh/Drum Separator

- Op

Tape Sealer

6-.Cooling, Sorting, Packaging and end of line

- Tape Sealer Type double Steel 50/12

- 50 = uses 50mm (perimeter ) of adhesive tape to seal. 12 = uses 12mm wide adhesive tape.

- The sealing system is quick and efficient, sealing from 900 to 1.000 packages per hour.

- Blades in stainless steel exposed with

Packing Funnel

6-.Cooling, Sorting, Packaging and end of line

- Simple device for packing whole chickens or ducks in polyethylene bags

- Table-mounted (table not included but can be supplied)

View product

Bird Bagging Machine

6-.Cooling, Sorting, Packaging and end of line

- The bird bagger is a single, pneumatically driven machine to bag birds;

- it can be expanded to a complete packing section, as multiple bagging machines can be installed on a sturdy stainless steel frame;

- each frame can be tailored to your specific needs

Bag Clipper

The Bag Clipper uses compressed air to semi-automatically seal (poly) bags with an aluminium clip. The device applies a consistent, secure and tight closing of the bag.

- Semi-automatic bag clipper to seal up to 1000 bags per hour

- Powered by compressed air

Water Screw Chilling

6-.Cooling, Sorting, Packaging and end of line

- Ideal for washing and pre-chilling eviscerated poultry prior to weighing, portioning and packing

- Prevent deterioration in meat quality and micobrial growth by lowering your product temperature

- Flexible set-up: comes in sections of 3 and 6 meters length

Spray Chilling

6-.Cooling, Sorting, Packaging and end of line

- Spray chilling system with Undine 1- or 2-mixing chamber manifolds

- Stainless steel protection shields

View product

Air Chilling

6-.Cooling, Sorting, Packaging and end of line

Controlled cool air flows are utilized to bring down the temperature of the product to the required level. Chilling by air is becoming the preferred cooling method in an increasing number of countries. The main reason is that it is a very hygienic process with ...

View productInside/Outside Bird Washer

The inside / outside bird washer thoroughly washes the interior and exterior of bird carcasses. Its washing units have spray pipes with high pressure spiraled nozzles which enter the carcass to clean and spray the bird from the inside. There are also multiple ...

View productFinal Inspection Machine

The final inspection machine is designed to clean the abdominal cavity of each carcass. Any remaining parts, such as lungs and other small residual tissues, are removed by a vacuum-powered suction head. The rotating machine holds up to 20 units. As each bird i ...

View productNeck Breaker

The neck breaker (cracker) is designed to remove necks automatically and without damage to the neck skin. The breaking units are guided by a cam and separate the neck from the spinal column. The double slide blocks provide a uniform neck breaking. The machine ...

View productCropper

The automatic cropping machine is designed to remove the crop (rests), trachea (windpipe) and oesophagus from birds as part of an automatic evisceration line. The birds are correctly positioned by guides. Stainless steel rotating drilling units enter the cavit ...

View productEviscerator

The automatic eviscerator is especially designed to remove the intestine package from the bird, without causing any damage to the organs or intestines. The evisceration spoon enters the carcass. After reaching the bottom of the cavity, the bracket turns and cl ...

View productOpener

Our automatic opener performs a clean, efficient cut without causing damage to the intestines. It is vital to make a precise cut as to not cut or puncture the intestines. The main task of the opener is to enlarge the opening in the vent made by the Vent Cutter ...

View productVent Cutter

The Vent Cutter is the first machine in the automatic evisceration line. It has a cylindrical, rotating knife which is used to make a circular cut around the vent of the bird. When the knife withdraws, it pulls out the vent without damaging or cutting the inte ...

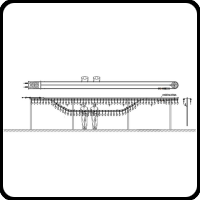

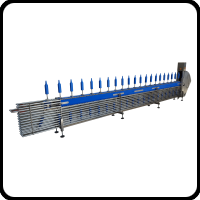

View productBleeding Line

2-.Stunning, killing and defeathering

- The bleeding line allows birds to bleed out after they have been killed.

- The birds hang from kill shackles and are conveyed by the overhead conveyor over a trough where the birds bleed out

- V-shaped, double-pass, standard sections with central drain

- Fu

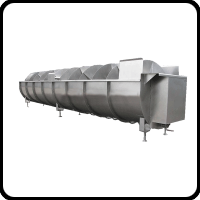

Scalder

2-.Stunning, killing and defeathering

Before plucking and after the birds have bled out, the birds are conveyed through a water tank filled with hot, scalding water. Hence the name of the machine: scalder or scalding tank. The water can be heated by heating elements and functions to help loosen th ...

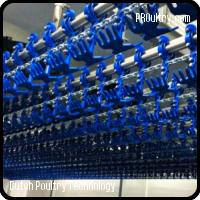

View productPlucker

2-.Stunning, killing and defeathering

- The defeathering machine is designed to remove feathers from poultry carcasses

- The machine consists of two plucking cabinets which contain V-belt-driven stainless steel rotating discs holding rubber picking fingers

- The picking fingers rub the feathers

Waterbath Stunner

2-.Stunning, killing and defeathering

- Correct stunning of the birds is essential for humane and efficient killing.

- Our waterbath stunner is a tried and tested method to tranquillize a bird before the kill cut is made.

- Model STN1200 with a capacity of up to 2000 birds per hour or model STN40