Eviscerator Alerta

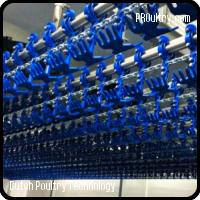

A product of Dutch Poultry Technology

Price and Availability

Price and Availability

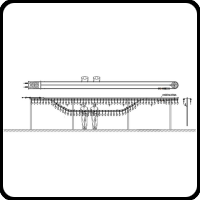

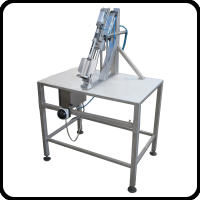

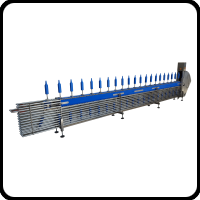

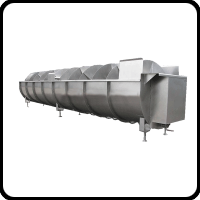

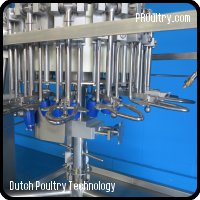

The automatic eviscerator is especially designed to remove the intestine package from the bird, without causing any damage to the organs or intestines. The evisceration spoon enters the carcass. After reaching the bottom of the cavity, the bracket turns and clamps the oesophagus. The spoon is removed from the bird and places the intestine package on the back of the bird to allow for veterinary inspection. Operators can remove hearts and lungs manually. Stomachs can be processed by a gizzard harvester and related machinery to obtain clean, peeled gizzards.

- Driven by the overhead conveyor

- Uses improved evisceration units

- The bird remains in the correct position during evisceration by using a centering bracket

- Dual function of the wing clamp: lift the thighs and hold the bird firmly

- The spoon removes the complete intestine package

- Made of stainless steel and other noncorrosive materials

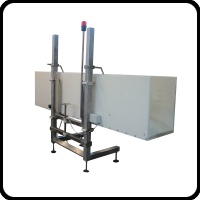

- Supplied with receiving bin with central drain

- Safety sensor which automatically halts the evisceration line upon detecting a machine jam or breakdown, preventing further damage to the line

- Height adjustment device

- High quality design

Product Videos 1 video

Related categories Eviscerator 1 Category

3-.Evisceration and chillingRelated Products 1 Product

Other products of Dutch Poultry Technology 1 producto

Product Website

http://www.dutch-poultry-tech.com/shop/evisceration/eviscerator/Dutch Poultry Technology

DUTCH POULTRY TECHNOLOGY B.V. is a Dutch manufacturing and engineering company specialized in the design, manufacturing and installation of cost-effective, reliable, easy to install and operate poultry processing solutions for processing 500 – 6000 birds per hour.

Our semi- and full automatic processing solutions are based on proven technology and 30+ years of automatic processing experience. Lean engineering and manufacturing greatly reduce production, installation and operation costs.

See company

Our semi- and full automatic processing solutions are based on proven technology and 30+ years of automatic processing experience. Lean engineering and manufacturing greatly reduce production, installation and operation costs.

See company

Price and product availability