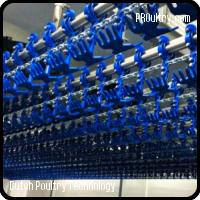

Scalder Alerta

A product of Dutch Poultry Technology

Price and Availability

Price and Availability

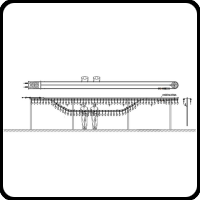

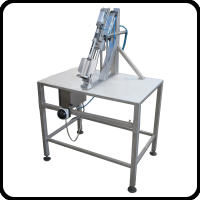

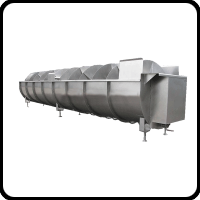

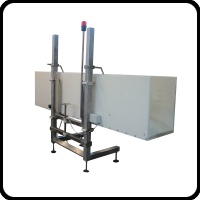

Before plucking and after the birds have bled out, the birds are conveyed through a water tank filled with hot, scalding water. Hence the name of the machine: scalder or scalding tank. The water can be heated by heating elements and functions to help loosen the feathers from the skin. This is absolutely vital to achieve a good defeathering result. Blowers inside the tank will create turbulence in the water, meaning the birds are completely immersed and scalded.

Three general scalding settings are:

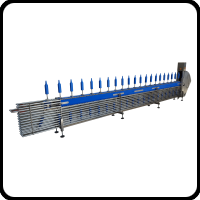

Integrated stainless steel double pass scalding tank*, 650 mm wide and 3700 mm long and an effective scalding length of 5 m , including:

Three general scalding settings are:

- soft/semi-scalding at 50-52ºC for 3 minutes

- medium scalding at 54-56ºC for 2,5 minutes

- hard scalding at 58-60ºC for 2 minutes

Integrated stainless steel double pass scalding tank*, 650 mm wide and 3700 mm long and an effective scalding length of 5 m , including:

- stainless steel radiators for indirect heating by hot water

- water agitation by means of a jet propeller driven by a motor

- temperature control unit

- water level control

Product Videos 1 video

Related categories Scalder 1 Category

2-.Stunning, killing and defeatheringRelated Products 1 Product

Other products of Dutch Poultry Technology 1 producto

Product Website

http://www.dutch-poultry-tech.com/shop/killing-and-plucking/scalder/Dutch Poultry Technology

DUTCH POULTRY TECHNOLOGY B.V. is a Dutch manufacturing and engineering company specialized in the design, manufacturing and installation of cost-effective, reliable, easy to install and operate poultry processing solutions for processing 500 – 6000 birds per hour.

Our semi- and full automatic processing solutions are based on proven technology and 30+ years of automatic processing experience. Lean engineering and manufacturing greatly reduce production, installation and operation costs.

See company

Our semi- and full automatic processing solutions are based on proven technology and 30+ years of automatic processing experience. Lean engineering and manufacturing greatly reduce production, installation and operation costs.

See company

Price and product availability