Container system Alerta

A product of MEYN FOOD PROCESSING TECHNOLOGY B.V.

Price and Availability

Price and Availability

Meyn containers are horizontally subdivided into four or five compartments by ‘animal friendly’ synthetic plates. Furthermore, Meyn containers have no lateral divisions. This provides better air circulation and means less stress for the birds and thus far fewer DOA’s (dead on arrival) in comparison to other container systems currently available.

OPERATIONS:

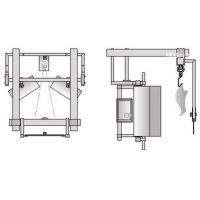

The tilting unit discharges the birds onto a conveyor by tilting the container to various angles of inclination ensuring all birds have been removed. An optional bird detection system can be mounted, alerting that a bird has remained in the container. Different actions are possible to discharge the remaining bird. The tilting unit can be equipped with a suction system to reduce free flying dust or may also be fitted with a water sprayer.

Having been discharged from the containers, the birds are guided to the hanging carousel by means of a modular supply belt. Sensors in the belt detect when birds are being unloaded and speeds up accordingly to prevent the birds landing on top of one another. The special modular belts in the Meyn system do not operate under tension. This provides for easy maintenance and repairs and prevents unnecessary wearing.

The hanging carousel features a round receiving bin, which helps to avoid supply congestion. In general, the handling conditions for the hangers are improved by the close proximity of the birds in the carousel to the shackles. The hanging carousel is equipped with its own driving unit making it independent of the overhead killing line. Furthermore, the carousel is supplied with a suction duct, for an easy connection of a dust collection system.

OPTIONS:

Automatic truck unloading/loading

Once arrived at the processing plant, the entire container is lifted from the delivery vehicle either automatically or by forklift truck. The system is equipped with one unloading/loading dock. More docks can be integrated, depending on the capacity and production facilities of the plant. With the Meyn container system automatic off-loading is performed by means of a skate conveyor that slides beneath the stacked containers. These skates then lift and retract with the containers to position them onto the buffer track where they are destacked and further transported to the tilting unit.

HIGHLIGHTS:

Robust and reliable construction with a very small chance of causing failures in the system.

Increased loading surface per container, allowing for higher truckloads within governmental regulations.

Open construction, improving the air flow through the container both during transport and waiting periods. The chance of suffocating the birds is reduced considerably.

Controlled dumping of the birds in tilting unit: efficient, high capacity and a minimum loss of quality.

Perfect hygiene as a result of container and truck floor design.

Flexibility in layout, ranging from basic to fully automated.

Automatic unloading and loading of truck at processor's site possible

Advanced system, which is still easy to operate and maintain due to a clever control system.

OPERATIONS:

The tilting unit discharges the birds onto a conveyor by tilting the container to various angles of inclination ensuring all birds have been removed. An optional bird detection system can be mounted, alerting that a bird has remained in the container. Different actions are possible to discharge the remaining bird. The tilting unit can be equipped with a suction system to reduce free flying dust or may also be fitted with a water sprayer.

Having been discharged from the containers, the birds are guided to the hanging carousel by means of a modular supply belt. Sensors in the belt detect when birds are being unloaded and speeds up accordingly to prevent the birds landing on top of one another. The special modular belts in the Meyn system do not operate under tension. This provides for easy maintenance and repairs and prevents unnecessary wearing.

The hanging carousel features a round receiving bin, which helps to avoid supply congestion. In general, the handling conditions for the hangers are improved by the close proximity of the birds in the carousel to the shackles. The hanging carousel is equipped with its own driving unit making it independent of the overhead killing line. Furthermore, the carousel is supplied with a suction duct, for an easy connection of a dust collection system.

OPTIONS:

Automatic truck unloading/loading

Once arrived at the processing plant, the entire container is lifted from the delivery vehicle either automatically or by forklift truck. The system is equipped with one unloading/loading dock. More docks can be integrated, depending on the capacity and production facilities of the plant. With the Meyn container system automatic off-loading is performed by means of a skate conveyor that slides beneath the stacked containers. These skates then lift and retract with the containers to position them onto the buffer track where they are destacked and further transported to the tilting unit.

HIGHLIGHTS:

Robust and reliable construction with a very small chance of causing failures in the system.

Increased loading surface per container, allowing for higher truckloads within governmental regulations.

Open construction, improving the air flow through the container both during transport and waiting periods. The chance of suffocating the birds is reduced considerably.

Controlled dumping of the birds in tilting unit: efficient, high capacity and a minimum loss of quality.

Perfect hygiene as a result of container and truck floor design.

Flexibility in layout, ranging from basic to fully automated.

Automatic unloading and loading of truck at processor's site possible

Advanced system, which is still easy to operate and maintain due to a clever control system.

Product Videos 1 video

Related categories Container system 1 Category

Bird transport cages or containersRelated Products 1 Product

Other products of MEYN FOOD PROCESSING TECHNOLOGY B.V. 1 producto

MEYN FOOD PROCESSING TECHNOLOGY B.V.

Meyn has been fully dedicated to poultry processing for many years now. Our knowledge, equipment, systems and services are available all over the world. Today we are very proud to be the dedicated business partner of numerous renowned poultry processing companies in over a hundred countries.

The world population continues to grow and the level of prosperity in upcoming markets is increasing rapidly. Global demand for animal protein is expected to grow accordingly. More mouths to feed means major market opportunities for your business, but it also brings serious challenges. How can you feed the world responsibly without jeopardizing your competitive edge and business continuity?

SOLUTIONS THAT MAKE YOU MORE SUCCESSFUL Working with Meyn means you can rely on intelligent, innovative, customized and sustainable solutions that enable you to meet the challenges of today’s market and tomorrow’s society. Your success is our goal. Every day, all over the world.

See company

The world population continues to grow and the level of prosperity in upcoming markets is increasing rapidly. Global demand for animal protein is expected to grow accordingly. More mouths to feed means major market opportunities for your business, but it also brings serious challenges. How can you feed the world responsibly without jeopardizing your competitive edge and business continuity?

SOLUTIONS THAT MAKE YOU MORE SUCCESSFUL Working with Meyn means you can rely on intelligent, innovative, customized and sustainable solutions that enable you to meet the challenges of today’s market and tomorrow’s society. Your success is our goal. Every day, all over the world.

See company

Price and product availability